ADVANCED PROTECTION FOR VITAL COMPONENTS

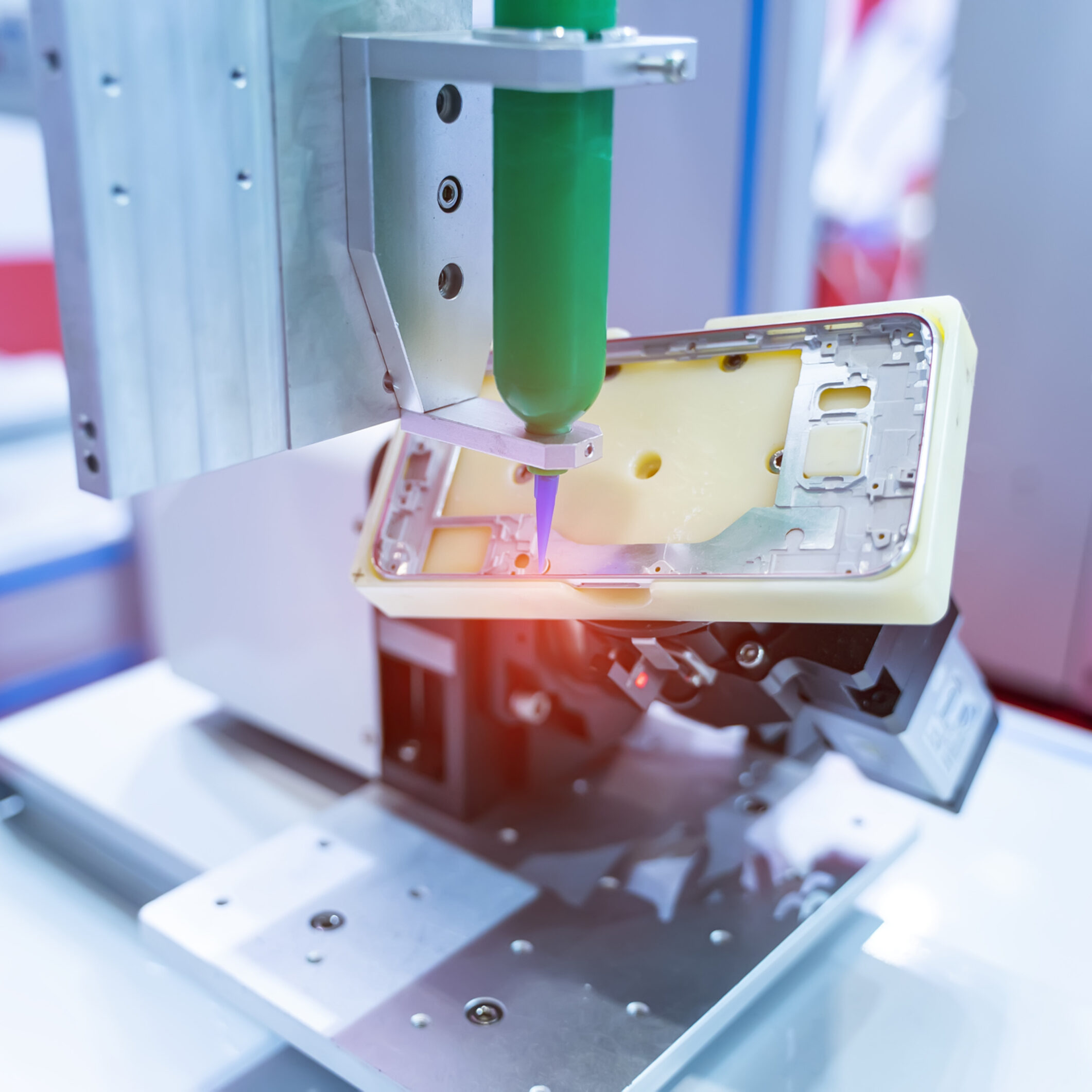

Precision in the Coating Process

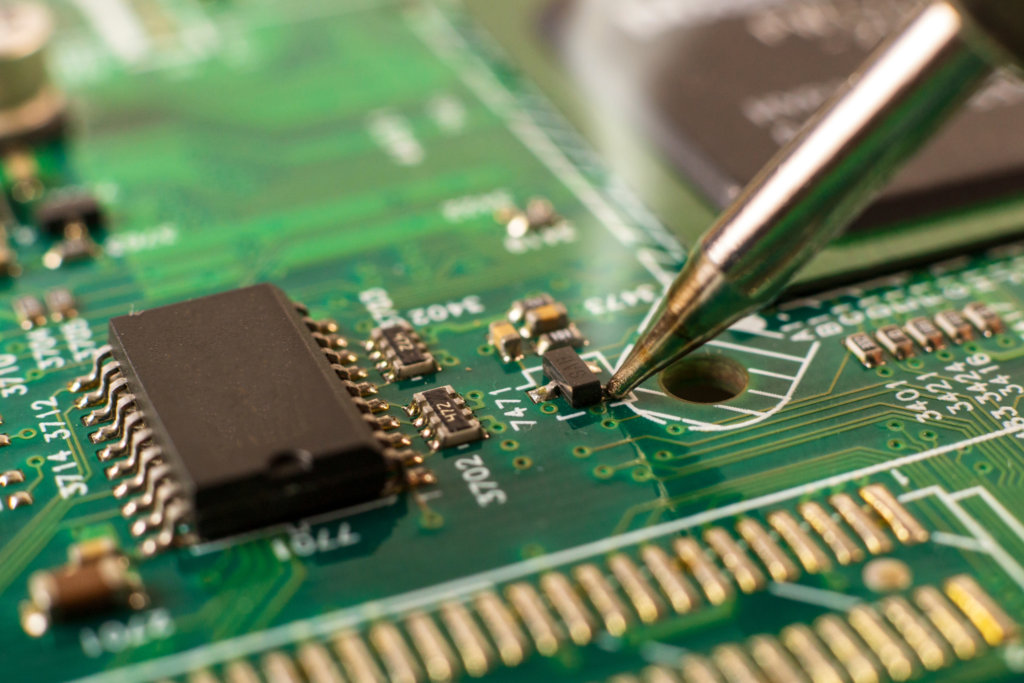

At ITP, our electronic boards coating service is synonymous of precision and reliability. This delicate process requires meticulous attention to details to ensure a complete protection of on board components.

We use advanced techniques to uniformly apply the resin, ensuring that every part of the electronic board results adequately protected from external agents such as humidity, dust and mechanical stress.

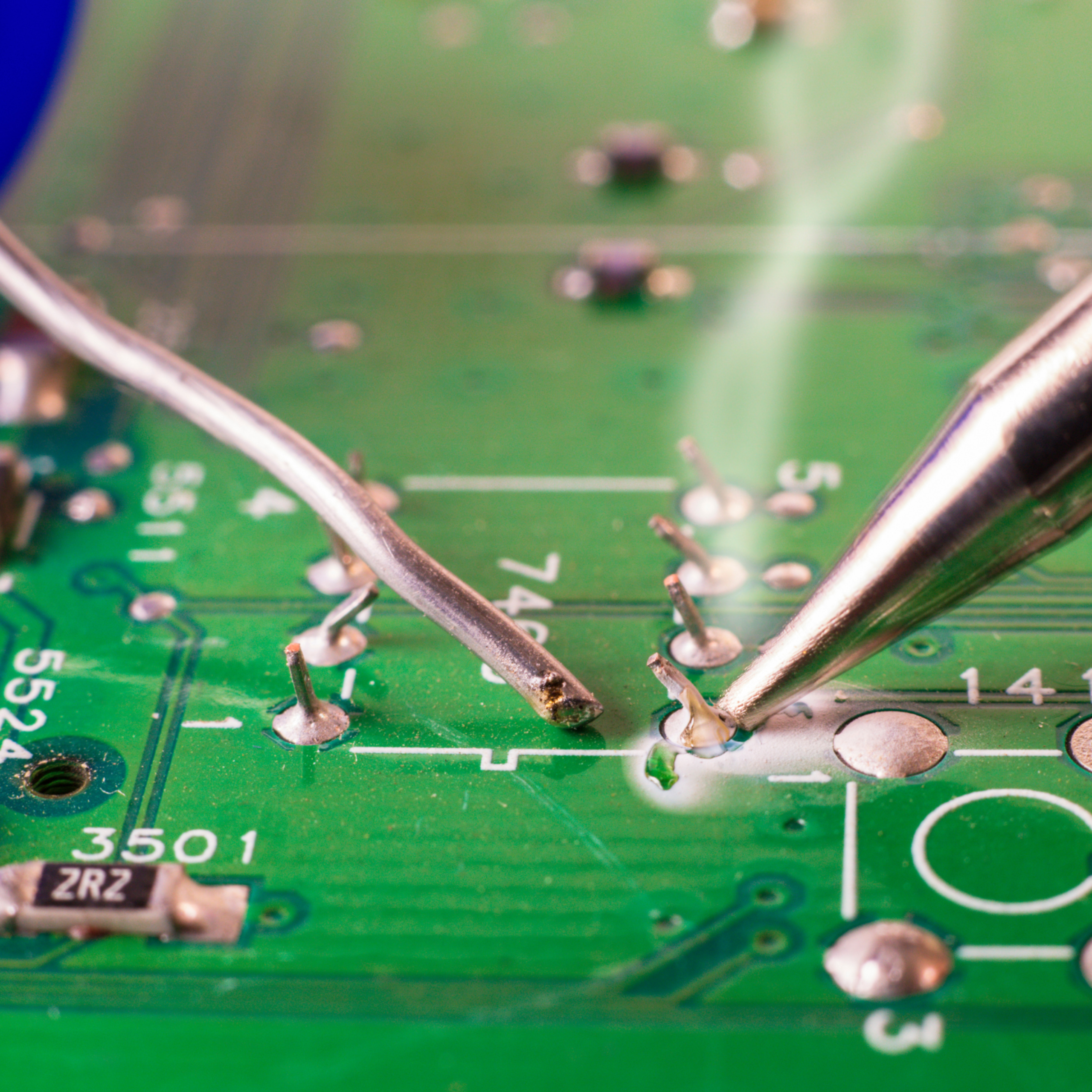

Superior Quality Materials

The use of high-quality materials is essential in the resin coating of electronic boards. We carefully select our resins to ensure the maximum protection level.

These resins have been tested to withstand harsh environmental conditions and thermal stresses, thus ensuring durability and reliability of the electronic boards in any operating environment.

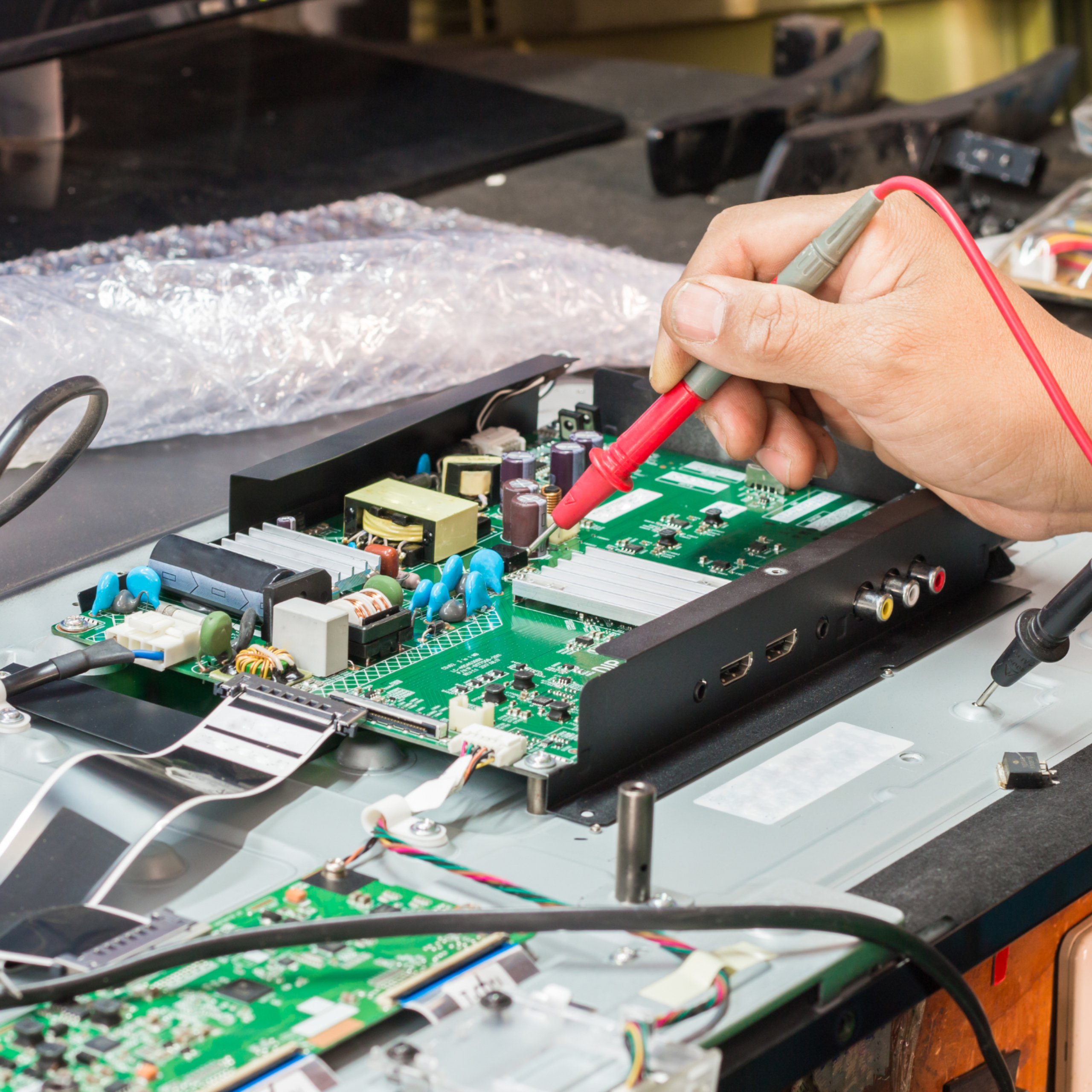

Custom Applications

We understand that each electronic board has unique needs depending on the application in which it will be used. We offer customized resin solutions, adaptable to the specific customer requirements.

Our team of experts works closely with customers to understand their specific needs and provide a coating service that perfectly fits their applications.

Rigorous Production Process

Each stage of our resin coating process is carefully monitored and controlled to ensure the highest quality.

From the electronic boards set up to the resin polymerization, each step follows rigorous quality standards. This process ensures that each treated board maintains its functionality and performance, effectively protecting it from external damage.